Automotive

Automate line-side supply, buffer staging, and sequencing with warehouse-grade precision.

From raw material to finished vehicle, Geekplus powers production logistics with robotics designed for takt time delivery, minimal labor, and real-time visibility.

40+

Projects Supporting Line-side Supply and In-plant Logistics

2.5x

Faster Component Delivery to Stations

98%

Reduction in Walking for Buffer Zone Operators

99.99%

Sequencing Accuracy

14+

Operators Saved in Large-scale Production Logistics Deployments

We understand Your Challenges

Automotive manufacturers face constant pressure from production variability, line-side bottlenecks, and labor shortages. Manual processes can’t keep pace with modern demand.

Peak Load Surges

Black Friday, 11.11, Ramadan

Geekplus robots collaborate with humans in the warehouses.

Multi-client & Multi-category Picking

Geekplus robots collaborate with humans in the warehouses.

Parcel Consolidation and last-mile Prep

Geekplus robots collaborate with humans in the warehouses, improving efficiency with combined precision and dexterity.

High-volume Reverse Logistics

Enable efficient coordination, accurate inventory management, and proactive decision-making with software integration.

Smart Solutions for Every Automotive Challenge

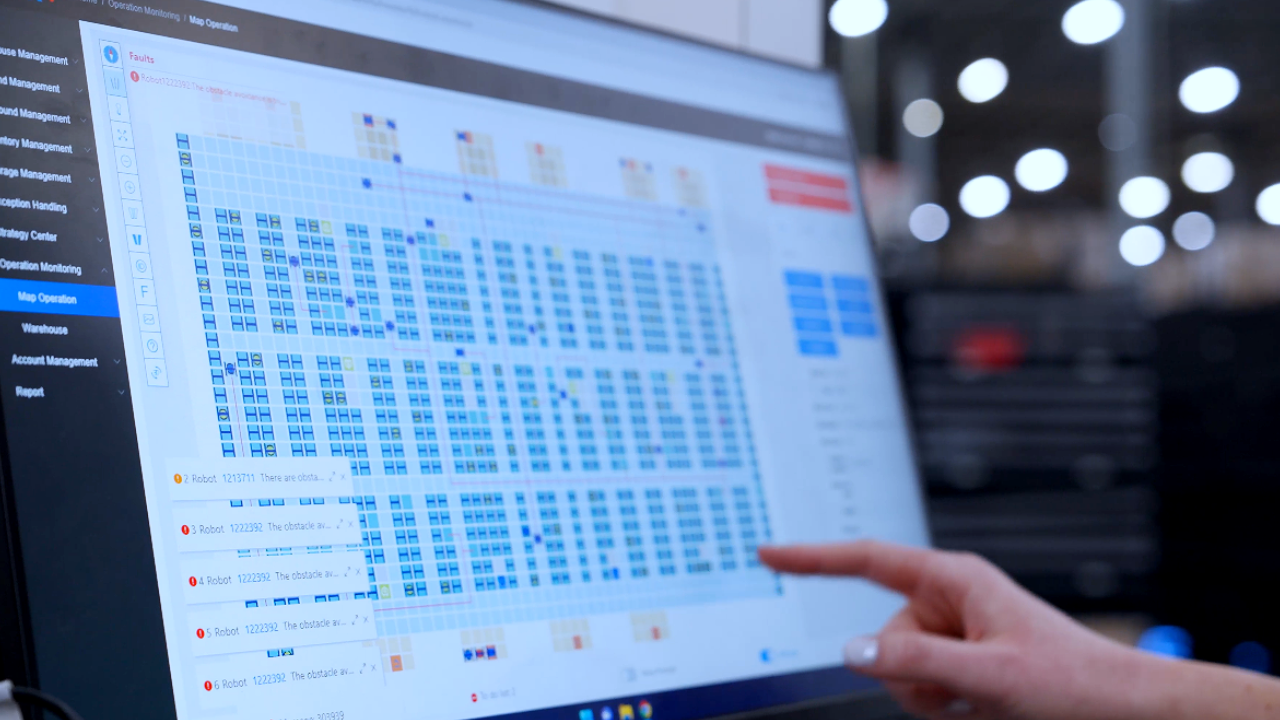

All powered by our Warehouse Execution System (WES) and Robot Management System (RMS)—to give you real-time visibility and orchestration across zones and clients.

Accelerate your line-side efficiency. Let Geekplus make it seamless.

Ideal for

OEM manufacturers

Tier-1 & Tier-2 suppliers

EV battery production

In-plant logistics & sequencing

Line-side delivery operations

& more...

One-stop Partner

for Warehouse Robotics

Built for Every Scenario in Automotive Manufacturing

Every client brings their own channels, rules, and delivery promises. We help you switch between them without switching up your operation. From retail pallets to DTC parcels, Geekplus helps Automotive Manufacturings run everything through one streamlined flow.

Inbound part receiving and buffering

Store parts by project, priority, or supplier batch

Just-in-sequence delivery to lines

Feed kits or modules in exact production order to match takt

QC and repair routing

Move rejected parts or assemblies to inspection or rework zones

Finished goods handling

Sequence by customer, model, or shipment route

Inter-line or inter-zone transfers

Move semi-finished goods between body, paint, and final lines

Built for Every Warehouse Process in Electronics

Reduce material handling time by up to 50% and increase throughput by 2–3×, all while ensuring ESD safety and material traceability.

Seamless integration of storage, picking, kitting, and line-feeding for electronics manufacturing.

Inbound Receiving (tray/tote/carton)

Automated Putaway with Storage Rules

Pick-to-kit Logic by BOM or Order

Sorting and Staging by Zone/Client

Buffer and QA Zone Management

Returns and Test-stage Reslotting

Storage types handled by Solutions

No two warehouses are alike. STP tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items

Storage Types

Handled with Shelf-to-Person Solution

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Item Sizes

Multiple sizes can be handled with this Solution

.png?width=333&height=232&name=Group%20237747%20(3).png)

Item Types Handled

Shelves can be configured to accommodate items of any shape and size

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

You need to streamline your production flow. Let us make that easy for you.

Take the first step toward smarter, faster manufacturing. Download the exclusive Automotive Production Optimization Kit and discover how Geekplus automation accelerates line-side delivery, sequencing, and material handling efficiency.

Why Automotive Manufacturers Choose Geekplus?

Modular by design

Launch fast, expand when ready

Works with any WMS

No full rip-and-replace needed

Fast payback

Typical ROI in < 2 years

Global support

40+ countries, multi-lingual ops teams

Client-level visibility

Show your customers real-time data they’ll love

What Our Customers Are Saying

.png)

"We boosted throughput by 250% without hiring. It feels like the shelves do the work."

Director of Fulfilment,

European Retailer

.png?width=2394&height=1336&name=a63627ba850b7c8c24ab0b68b5525d7060361387%20(1).png)

3x more throughput

99.9% Accuracy

300% increased efficiency

Read Success Stories

Let's turn your warehouse into a growth engine 🎯

Reach out to our team for enquiries, sales, virtual demo, live demo and other informations

Downloads

Retail & Supply Chain Dive

29 December, 2025

How Covid-19 has affected the supply chain

29 December, 2025

Cold Chain: Temperature-controlled supply chains

29 December, 2025

FAQs

Geek+ Shelf-to-Person solutions provide real-time inventory management, ensuring accurate and transparent data. This minimizes the risk of production line shutdowns and improves overall operational efficiency.

Yes, Geek+ Moving systems automate payload delivery, eliminating the need for manual material handling. Smart algorithms enable large-scale delivery scheduling, improving efficiency and ensuring safe operations.

Geek+ builds flexible manufacturing systems with smart robot technology. Adjustable production lines can be quickly deployed or modified to meet changing operational needs, reducing downtime and investment costs.

By automating material handling and reducing mixed man-machine operations, Geek+ systems significantly lower safety risks in automotive warehouses and manufacturing environments.

Geek+ systems are modular and can be expanded based on production capacity requirements. Robots can be easily added or removed, ensuring seamless scalability as business needs evolve.

Related articles

Where it all started? The Journey of ...

10 March, 2025

Industries moving forward with robotics ...

10 March, 2025

.png?width=300&height=300&name=Manufacturing_0008_BMW%20(1).png)

.webp)

.webp)