General Merchandise & Retail

Powering the Engine Behind Retail Growth

Smarter warehouse automation for grocery, convenience, DTC, B2B, and omnichannel retail.

From cost center to growth engine — built for retail speed and scale.

200+

Retail Projects Live

10,000+

AMRs Deployed in Retail Operations

3x

Operational Efficiency

99.99%

Picking Accuracy

What Our Customers Are Saying

.png)

The logistics park is equipped with AMR robots, shuttle rack systems, and automatic goods yards that are rarely seen in Taiwan to enhance shipping efficiency, through cross-industry alliances with strategic partners, we optimize warehouse and logistics efficiency and strengthen the competitiveness of our e-commerce business. "

Alice Chang,

CEO and general manager of PChome

.png)

After adopting the Geek+ robots, we are better able to handle our stocks and can offer a more comfortable workplace to our employees.”

Sebastian Wiradharma,

Director of Asia PetWorld

We understand Your Challenges

From multi-format distribution to last-mile complexity, we help you solve the toughest issues across store and DTC fulfillment.

Multi-format Inventory and SKU Growth

General merchandise, perishables, promo packs, and DTC SKUs require mixed picking flows.

Split-case and Piece-pick Complexity

Traditional systems struggle to handle high-volume, high-variation order profiles.

Tight SLAs and Last-mile Expectations

Staging and dispatch delays can lead to missed cutoffs and unhappy customers.

Returns and Reverse Logistics

Managing rebin, restock, and defective returns adds major inefficiency.

Seasonality and Volume Surges

Campaign spikes and flash sales demand fast, scalable response.

Limited Floor Space in Urban Centers

High rent and low ceiling height call for smarter vertical storage.

High Employee Turnover

Manual training takes time and leads to inconsistency across shifts.

Inventory Visibility Gaps

Disconnected systems limit real-time insights and control.

Inflexible Infrastructure

Difficult to respond to new retail formats or business shifts quickly.

Smart Solutions for Every General Merchandise & Retail Challenge

All powered by our Warehouse Execution System (WES) and Robot Management System (RMS)—to give you real-time visibility and orchestration across zones and clients.

From omni-channel to last-mile, see how retailers are using robotics to stay ahead.

Ideal for

Retail DCs

Franchise distribution

Omnichannel nodes

Dark stores

Urban MFCs

E-commerce hubs

Grocery backends

One-stop Partner

for Warehouse Robotics

Scenarios We Simplify for General Merchandise & Retail

Complex logistics. Clean execution. From flash sales to reverse logistics, we simplify what slows you down—so you can serve more clients, faster.

Store and online fulfillment in one

Run B2B and B2C flows side-by-side, assign zones by order type or client.

Return Processing

Fast restock, QC, and reallocation of returned goods to active inventory.

Cross Docking

Receive and forward goods without long-term storage.

Last-mile staging and routing

Sequence outbound waves and load by zone or time window.

Seasonal surges and campaign support

Adapt throughput instantly without structural change.

Dark store replenishment

Deliver daily batches by priority and proximity.

Click & collect fulfillment

Automate staging by store, batch, or customer order.

Franchise network distribution

Separate flows, quotas, and timelines for multiple locations.

B2B + DTC hybrid operations

Combine pallet-in/piece-out with zone-based automation.

High-SKU, low-order frequency scenarios

Balance dense storage with fast access logic.

Warehouse Processes You Can Automate

Reduce operating cost per order by up to 40-50%, and increase throughput by 2–4X—without touching your building structure.

Seamless integration of all processes for General Merchandise & Retail industry.

Inbound/Put away

- Smart putaway based on SKU velocity, size, and value

Storage Optimization

- Dynamic slotting to improve density without sacrificing access

Picking

- Batch, zone, or wave picking supported across all flows

Sorting and Routing

- Auto-direct to lanes, cages, or outbound zones by delivery type

Outbound Staging

- Buffer for loading by cut-off time or customer promise

Returns

- Rebin, scan, and route to resale or secondary paths

Inventory Replenishment

- Trigger restock logic based on buffer or real-time depletion

Order Consolidation

- Merge items from different picking zones into single packout

Storage types handled by Solutions

No two warehouses are alike. STP tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items.

Storage Types

Handled with Shelf-to-Person Solution

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Item Sizes

Multiple sizes can be handled with this Solution

.png?width=333&height=232&name=Group%20237747%20(3).png)

Item Types Handled

Shelves can be configured to accommodate items of any shape and size

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Need to convince leadership to invest in fulfillment automation? Use this kit.

Retailers are automating store replenishment and ecom fulfillment. Use these examples to get decision-makers aligned.

Why General Merchandise & Retail Operators choose Geekplus?

Modular by design

Launch fast, expand when ready

Works with any WMS

No full rip-and-replace needed

Fast payback

Typical ROI in < 2 years

Global support

40+ countries, multi-lingual ops teams

Client-level visibility

Show your customers real-time data they’ll love

Read General Merchandise & Retail Success Stories

Let's talk Retail automation 🎯

Turn your warehouse into a retail growth engine.

Downloads

F Series Product Fact Sheet

27 January, 2026

S Series Product Fact Sheet

27 January, 2026

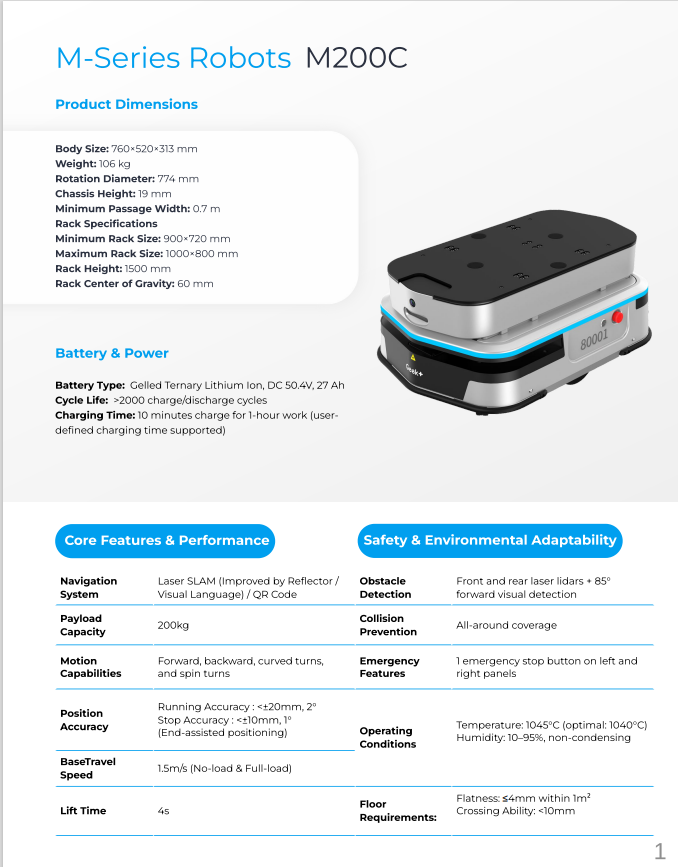

M Series Product Fact Sheet

27 January, 2026

FAQs

Geekplus solutions, such as the Shelf-to-Person system, reduce manual handling and walking by bringing items directly to operators. Intelligent wave grouping and automated order arrangement optimize efficiency for heavy and bulky items like beverages, rice, and oil.

Yes, Geekplus systems, including the Four-Way Shuttle and Tote-to-Person solutions, maximize vertical and horizontal space. These systems increase storage capacity by up to 5 times compared to traditional methods, accommodating a wide range of product sizes and categories.

Geekplus systems use visual picking and smart monitoring to ensure high accuracy. For example, the Shelf-to-Person PopPick system achieves dense storage with only 2cm tote spacing, while ergonomic workstations improve picking efficiency and accuracy.

Absolutely. Geekplus systems enable mixed storage of large, medium, and small items, as well as full cartons and individual pieces. Robots transport items from different storage areas to workstations for one-stop picking, reducing the need for manual consolidation.

Geekplus offers modular and flexible systems that can be deployed in stages based on business needs. Features like predictive maintenance, real-time monitoring, and seamless integration with existing systems ensure reliable operations and easy scalability.

Related articles

Where it all started? The Journey of ...

10 March, 2025

Industries moving forward with robotics ...

10 March, 2025

.png?width=300&height=300&name=Retail_0001_walmart%20(1).png)

.webp)

.webp)

.webp)