Shelf-to-Person PopPick

Flexible Order Fulfilment from Pieces to Pallets. Any size. Any scale.

Built for Your Warehouse.

Optimized for your layout, SKU mix, and growth goals, Geekplus Shelf-to-Person system scales effortlessly with your operations and demand cycles.

Every step in the warehouse costs time, money,

and morale. Walking. Searching. Reaching. Repeating.

What if inventory came to your team instead?

Geekplus Shelf-to-Person brings entire shelves directly to your operators. Accelerate picking, reduce walking, deploy with minimal downtime and infrastructure changes and scale easily. Onboarding takes minutes, and the ROI starts showing fast. Built for growing warehouses with high SKU complexity.

Flexible. Scalable. Customisable.

One System. Two configurations. One mission: faster, smarter fulfillment.

PopPick V2.0 Solution

Shelf-to-Person

Standard Configuration

Shelf-to-Person

PopPick Configuration

Upgrade

Description

Fast setup, proven performance

Mobile Robots bring full shelves to your operators. Simple, scalable, and fast to deploy. Ideal for warehouses starting their automation journey with a broad range of SKUs.

High throughput, dense storage

Meet the ultimate upgrade. Robotic arms deliver totes from shelves to operator workstation for faster, ladder-free ergonomic picking. Designed for high-throughput and storage, fast-moving SKUs, and peak season agility

Solution Components

Picking Workflow

Full Shelves delivered to operator, Pick from front or side

Standard + Tote automatically delivered via robot arm, side-picking for smaller shelves and pallets

Shelf Height

Up to 2.8m

Standard + Extended height up to 3.7m

Storage Density

Modular accommodating Pieces, Pallets, Cartons, Laminates, Hanging shelves

Standard + Modular racks + dense tote storage

Slotting & Hit Rate

ABC Rearrangement based on order volume predictions, Smart algorithms sort inventory during off-peak/idle hours

Standard + Dynamic slotting within the shelf optimised by order data, SKU popularity, Optimisation during idle time

Workstation

Light projection-aided, Pick-to-light

Standard + Automated tote retrieval, ergonomic layout, robot-arm, 3 cache totes places.

Ergonomics

Zero walk path, optional ladder to assist

Standard + No-ladder, optimised pick height, reduced strain

Operational Throughput

Up to 3x faster than manual

Standard + Higher throughput, Up to 4x faster, improved hit rate

Use Cases

Simpler ops, Wide SKU variety, fast ROI

Standard + Dense storage, fast movers, peak handing, ergonomic workflows

Robot Used

P-Series P800 / P500 / P1200

P-Series P800H/P1200

Non-Workstation Picking

Pallets, Cartons, Oversized SKUs picked from shelf side

Standard + Side picking enabled for pallet racks and non -tote items

Deployment Time

~ 1-2 months based on Warehouse size

~ 1-2 Weeks based on Warehouse size

Use Cases

Industries Served

Apparel, 3PL, Retail, eCommerce, Electronics, Cosmetics, B2B, and B2C industries.

Oversized SKU Handling

Picked from side of the workstation

Scalability

Add robots, Racks or Work-stations based on demand

Shared

Deployment Time

~ 1-2 months based on Warehouse size

Software Platform

RMS (robot scheduling), WES (task logic), IOP (alerts), G-plan (simulation)

PopPick V2.0 Solution

Shelf-to-Person |

Shelf-to-Person |

|

|---|---|---|

Description |

Fast setup, proven performance

Mobile Robots bring full shelves to your operators. Simple, scalable, and fast to deploy. Ideal for warehouses starting their automation journey with a broad range of SKUs. |

High throughput, dense storage

Meet the ultimate upgrade. Robotic arms deliver totes from shelves to operator workstation for faster, ladder-free ergonomic picking. Designed for high-throughput and storage, fast-moving SKUs, and peak season agility |

|

Solution Components |

||

Picking Workflow |

Full Shelves delivered to operator, Pick from front or side |

Standard + Tote automatically delivered via robot arm, side-picking for smaller shelves and pallets |

Shelf Height |

Up to 2.8m |

Standard + Extended height up to 3.7m |

Storage Density |

Modular accommodating Pieces, Pallets, Cartons, Laminates, Hanging shelves |

Standard + Modular racks + dense tote storage |

Slotting & Hit Rate |

ABC Rearrangement based on order volume predictions, Smart algorithms sort inventory during off-peak/idle hours |

Standard + Dynamic slotting within the shelf optimised by order data, SKU popularity, Optimisation during idle time |

Workstation |

Light projection-aided, Pick-to-light |

Standard + Automated tote retrieval, ergonomic layout, robot-arm, 3 cache totes places. |

Ergonomics |

Zero walk path, optional ladder to assist |

Standard + No-ladder, optimised pick height, reduced strain |

Operational Throughput |

Up to 3x faster than manual |

Standard + Higher throughput, Up to 4x faster, improved hit rate |

Use Cases |

Simpler ops, Wide SKU variety, fast ROI |

Standard + Dense storage, fast movers, peak handing, ergonomic workflows |

Robot Used |

P-Series P800 / P500 / P1200 |

P-Series P800H/P1200

|

Non-Workstation Picking |

Pallets, Cartons, Oversized SKUs picked from shelf side |

Standard + Side picking enabled for pallet racks and non -tote items |

Deployment Time |

~ 1-2 months based on Warehouse size |

~ 1-2 Weeks based on Warehouse size |

|

Use Cases |

||

Industries Served |

Apparel, 3PL, Retail, eCommerce, Electronics, Cosmetics, B2B, and B2C industries. |

|

Oversized SKU Handling |

Picked from side of the workstation |

|

Scalability |

Add robots, Racks or Work-stations based on demand |

|

|

Shared |

||

Deployment Time |

~ 1-2 months based on Warehouse size |

|

Software Platform |

RMS (robot scheduling), WES (task logic), IOP (alerts), G-plan (simulation) |

|

Quick Deployment

Simple to use, quick to deploy, easy to relocate, adapts to the varying business scenarios of customers.

Easy Installation

PopPick Lite combines plug-and-play simplicity with customizable configurations. Workstations can be installed by 2 people in 2 hours, with full system deployment in less than two weeks.

Flexible and Scalable

Supports on-demand expansion, movable racks, flexible layout, Mixed storage and picking, compatible with small, medium, and large Items.

Ergonomic Picking

Compared to manual warehousing, picking efficiency is increased by 2-4 times, Automated tote retrieval and placement, Unmanned automated dynamic sorting during night or downtime, high accuracy

Your One-stop Partner for Warehouse Robotics

Built to Meet Every Industry Demand

One platform. Any vertical. Unlimited adaptability.

No two warehouses operate the same. STP adapts to your specific footprint, SKU mix, and throughput requirements—delivering seamless performance across every item size, shape, and level of complexity.

3PL & E-commerce

Serve diverse clients with dynamic inventory, fast turnarounds, and unpredictable peaks.

SKU Complexity : High

Multi-client Agility + Dense Storage

Built for Multi-tenant fulfilment, cross-border logistics, D2C enablers.

Geek+ Solution

B2B Retail Distribution

Bulk replenishment, tight SLAs, and channel-specific requirements.

SKU Complexity : Medium

High-throughput + Replenishment Precision

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

OmniChannel

Click-to-store, D2C, in-store fulfilment.

SKU Complexity : High

High Configurability + Flexible Wave/batch Picks

Built for Department stores, regional fulfilment hubs, omni-channel DCs.

With Geek +

Grocery Retail

From chilled to ambient, STP supports zone-based picking with speed and safety, perfect for high-velocity, time-sensitive orders.

SKU Complexity : Medium

Zone Picking + Freshness-first

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

Apparel & Footwear

Perfect for high-SKU, low-unit warehouses. Manages seasonality, returns, and odd-shaped items with ease.

SKU Complexity : Medium

Flexible Wave/batch Picks

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

Geek+ Solution

Any Industry

Bulk replenishment, complex SLAs, and omni-channel logistics.

SKU Complexity : Medium

Flexible Wave/batch Picks

Built for National retail DCs, franchise distributors, multi-format B2B hubs.

With Geek +

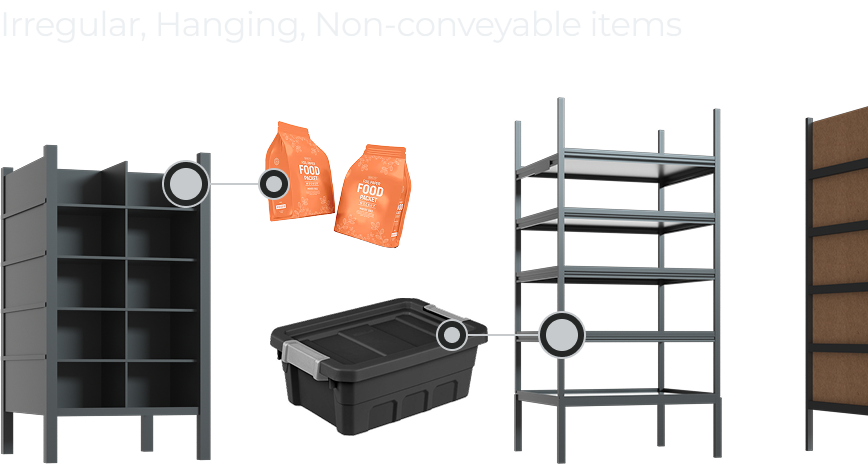

Built for Every Storage Type in Your Industry

No two warehouses are alike. STP tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items

Storage Types

Handled with Shelf-to-Person Solution

.png?width=491&height=232&name=Frame%201171275885%20(1).png)

Item Sizes

Multiple sizes can be handled with this Solution

Item Types Handled

Shelves can be configured to accommodate items of any shape and size

Built for Every Process in Your Industry

All warehouse processes can be managed by Geekplus System and Solution with ease.

Storage

Supports various item sizes and SKU types, catering to diverse industry storage requirements.

Dynamic Slotting

Shelves with high activity are moved closer to workstations to reduce handling distance and boost storage efficiency.

Consolidation & Packing Prep

PopPick enables batch picking and multi-order consolidation at the workstation.

Internal Transport

Mobile robots handle shelf movement across zones without fixed infrastructure.

.png?width=1280&height=720&name=STP--transport(1).png)

Picking

Robots bring inventory shelves directly to workstations, eliminating walking and search time.

Modular Architecture, Not Fixed

Geekplus Shelf-to-Person brings entire shelves directly to your operators for lightning-fast picking, reduce walking, speed up the fulfilment, and make onboarding nearly instantaneous. Ideal for small to mid-sized warehouses with a wide range of SKUs. Choose PopPick for maximum throughput and smallest footprint.

Robots

P Series

Geekplus multiple-model picking robots, with their maximum load of 1200kg and their ability to reduce 50-70% of manual labor and increase picking accuracy to 99.99%, is the preferred choice for businesses looking to reduce costs and raise efficiency using automated warehouse robots.

P500

P800

P1200

.png?width=306&height=215&name=Rectangle%2015187%20(1).png)

Shelves & Racks

Customisable as per industry

Meet the storage requirements of large, medium and small pieces at the same time, and there is no need for complicated combined order operations in the future

Compatible with popular and long-tail items, suitable for multi-industry storage needs.

Workstations

Multi - type workstations to meet various needs

Geekplus offers a line of innovative workstations, including the P-Series, PopPick Lite, and PopPick Lite docking conveyors, designed for high throughput, strong compatibility, and large storage. These workstations deliver safe, efficient order picking with a user-friendly, ergonomic design that boosts productivity and user experience.

All-in-One Software

Multiple options for your customs needs

The Geekplus Software Suite is a series of modular software products to support efficient, reliable and flexible robot-based smart warehouse solutions.

The Geekplus Software Suite supports multiple languages and provides open interfaces, ensuring that customers and partners can easily use and integrate with.

Core Software

WES RMS IOP

Easy Integration

WMS ERP MES

Simulation & Visualization

G-Studio

3D Real-time Data

System Portal

Safety & Security

Algorithm and data driven

Geekplus has a professional safety design, safety research and development, safety implementation, and safety verification team to ensure the safety of each project. The complete system security solution has been certified by TUV-Rheinland and can provide functional safety protection up to PLd.

Shelf-to-person Workflow

Geek+ Shelf-to-Person is built for scale, speed, and smart orchestration.

Orders enter the WMS/WES.

Geekplus RMS assigns mobile robots to retrieve required shelves.

Shelves are brought directly to a picking station.

The operator picks and confirms.

Robot returns the shelf or sends it for replenishment.

Integrations & Tech Stack Compatibility

- Compatible with major WMS/ERP systems

- Seamless REST API + Webhook support

- Cloud or on-prem deployment options

- Real-time dashboards for ops visibility

- IT support model with 24/7 monitoring

What Our Customers Are Saying

.png)

together with partners like Geek+, has helped us to maintain an efficient flow of goods, enhanced shipping performance, and reliability in light of the steady growing pressure of customer demands."

András Táncsics,

CEO of Boxy

.png)

This automated warehouse picking system has been a wise financial decision. We can now significantly increase the amount we pick, pack, and ship… the system is paying for itself."

Shabbab Al-Ghamdi,

co-founder of RangePlus

More Success Stories

FAQs

The STP solution brings shelves directly to operators, minimizing walking time and streamlining workflows. This automation accelerates order picking, increases accuracy, and allows warehouses to handle higher volumes with fewer delays.

Businesses implementing the STP solution typically see a reduction in labor costs of up to 50% and faster order fulfillment. The efficient use of space and improved picking speeds result in significant cost savings, especially during peak demand periods.

Yes, the STP solution is highly scalable. Adding shelves, robots, or workstations is seamless and ensures the system evolves with your operational needs, whether you’re expanding product lines or entering new markets.

The STP solution features advanced integration capabilities, allowing easy connectivity with major Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms. This ensures operational workflows remain uninterrupted.

The STP solution is equipped with predictive maintenance tools, real-time error notifications, and advanced diagnostics. Combined with continuous technical support and preventive services from Geekplus, these features ensure reliable and uninterrupted operations.

Related articles

Intelligent Order Fulfillment Strategies: ...

29 September, 2025

Why S&S Activewear chose Geek+ 5 times in 3 ...

27 June, 2025